Ishikawa diagram 6m sample license#

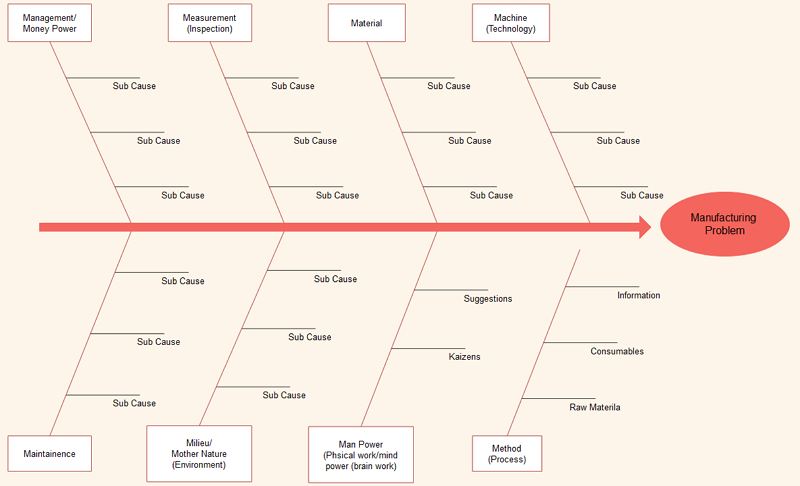

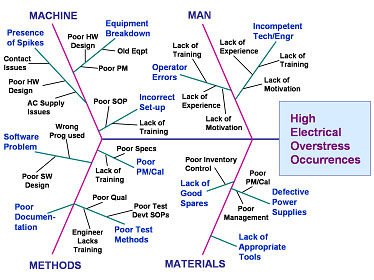

Here it can be from lack of maintenance to not paying for the license of a program essential for production or lack of skills to manage it. Machine certainly refers to factories, but for application in other contexts, this point of analysis can be interpreted as tools used to execute processes. The methodology behind the process can be the cause of numerous issues within an organization, so this M aims to understand how the way the work is developed influences the problem.

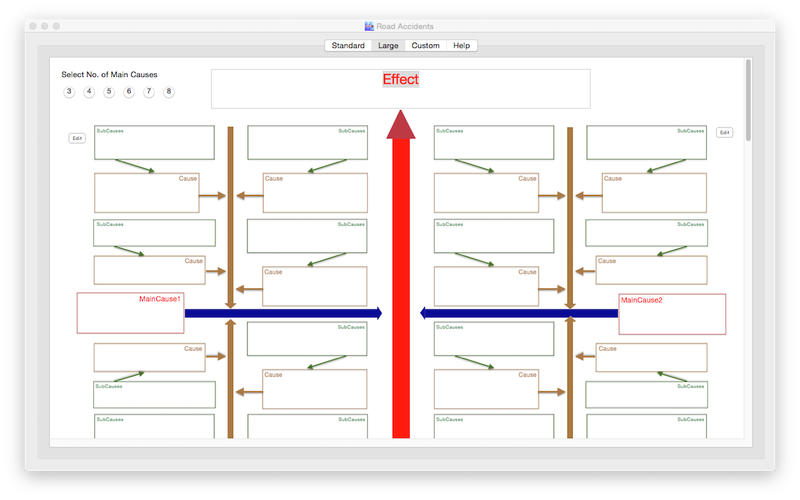

Ishikawa diagram 6m sample how to#

This name comes from the fish bones, see, each of them represents a possible cause of the effect (problem) being analyzed. Each of them starts with the letter M and there are 6 in total.īelow, you will understand what each of these items is and how to determine them. Ishikawa diagram example Understand what the 6Ms of the Diagram are

We come to the practical part of this text, we will teach you how to apply the Fishbone Diagram in practice, helping you to identify the primary cause of problems.īut before going into these details, we need to explain why this methodology is also known as the 6M Diagram. Yes, there are several names, but once you finish this text you will understand why all of them and you will not get confused. Since 1943, the year of its creation, the methodology has gained increasing popularity, as it helped employees from different areas to evaluate their processes and resolve issues that affect the organization’s productivity . Ishikawa diagram exampleĪs you can imagine, the name of the methodology comes from its creator, who was called Kaoru Ishikawa, an engineer who developed a tool with the objective that it could be used by anyone, from employees on the “factory floor” to the board of directors. Now that you understand what the Ishikawa Chart is and how it is applied within the corporate environment, let’s talk a little about its history. Thus, it is very useful during the decision-making process and drives the continuous improvement of processes, especially if associated with other management tools . Something managers should keep in mind when adopting the Ishikawa Matrix is that it is not just for organizational issues, as we mentioned earlier, even the constant delays of an employee can be addressed in this way. Thus, even the HR team can take advantage of this methodology.

0 kommentar(er)

0 kommentar(er)